Case Study

This case study shows how “Chemical Analyzer” by ViridisChem (a web-based tool offered through yearly subscription) can be used to evaluate the toxicity of raw materials used during the drug development process, and find better alternatives.

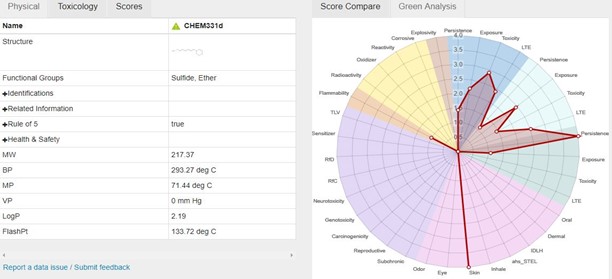

Chemical Analyzer offers toxicity analysis of any known or unknown chemical and shows it in easy to understand visual graph. It offers 48 different physical and toxicological properties, and based on these properties, provides ecological, health and safety scores, that can be drilled down to individual end-points that influence these scores (as seen below).

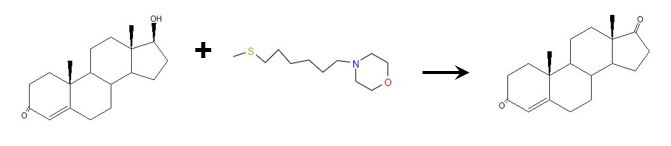

For this case study, we have used the well-known Corey-Kim oxidation example which produces keto-testosterone from the Testosterone molecule. We will cover:

- How to use toxicity evaluation of raw material to identify areas of improvement

- How to evaluate the toxicity of a new molecule based on structure (Schembl-1666920 in the example below)

- How to find less toxic reagents

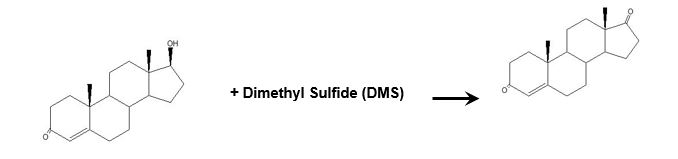

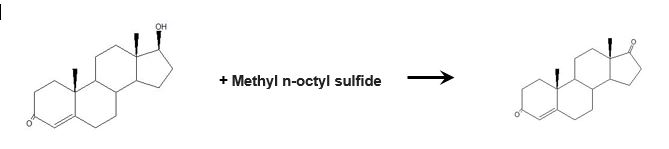

First Method

The original development method used Dimethyl Sulfide (DMS) as a reagent with catalysts N-Chlorosuccinamide, and Triethyl Amine.

As you can see, Dimethyl Sulfide has a strong odor, toxic if inhaled or swallowed, severe skin irritant, and is very volatile. The reaction also needs the toxic catalysts N-Chlorosuccinamide and Tri-ethyl Amine which themselves have toxicity concerns, and prolonged exposure causes organ damage. In short, this method has serious lab-safety concerns, and is not sustainable.

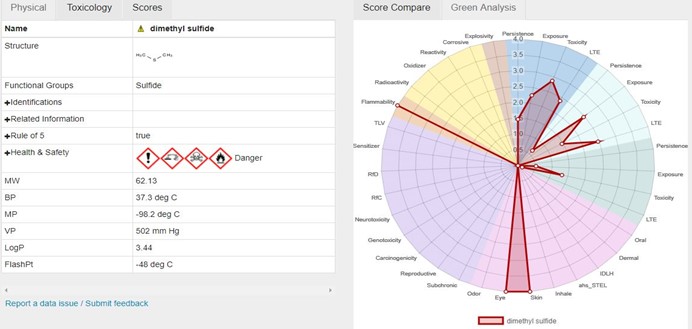

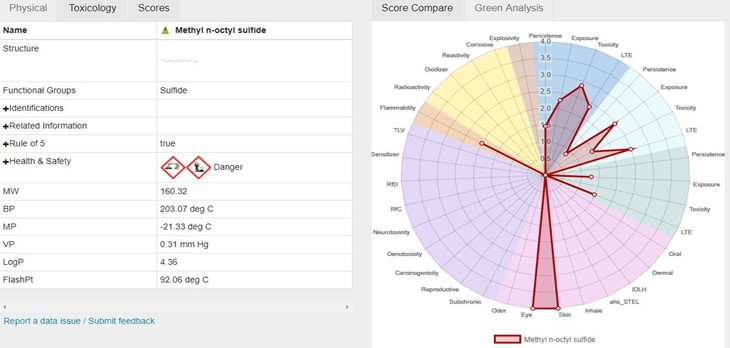

Second Method

To avoid the use of Dimethyl Sulfide, alternate method was devised that used toluene and the reagent Methyl n-octyl sulfide which is odorless and fluorous.

But as you can see, Methyl n-octyl sulfide though less toxic than dimethyl sulfide, is still eye and skin irritant. The overall reaction still has high toxicity footprint; and it uses the toxic catalyst triethyl amine along with VOC Toluene.

Third Method

This method was then further improved using Schembl-1666920 which is water-soluble and is odor-free, although it does have some water and soil toxicity concerns.

Approach using ViridisChem’s Chemical Analyzer

If ViridisChem’s Chemical analyzer was available during this process improvement from the original method to the final green method, scientists could have used it to explore the less toxic reagents. Its powerful advance search feature allows you to search for chemicals that satisfy reaction-specific criteria like:

- Must have functional group needed for oxidation reaction with sulfur

- Must be odorless, non-volatile (flash point > 1000C), and maybe water-soluble?

- Must not be eye-irritant, or skin-irritant (or those scores should not be greater than 2)

It identifies a shortlist of alternative reagents so that your process improvement effort is more focused. Of course, in practice, there are many other factors that must be taken into account, such as:

- Amount of the compound needed, availability in large quantity, and cost

- If the reaction requires a strong or weak oxidizing agent

- Will the water-soluble compound increase energy usage? Will the effort of eliminating water from the resultant mixture impact the end compound, or its yield? Or will the reaction time be impacted?

ViridisChem is a software company offering essential toxicity data and tools for companies to move towards sustainable product development.

We have the world’s most comprehensive toxicity database with over 90 million chemicals, and utilizing this data, our software tools provide toxicity analysis of chemicals, mixtures and formulations, and product development processes.

Demonstrations

Chemical Analyzer for Lab Safety

Chemical Analyzer for Process Development